Thermal Analysis

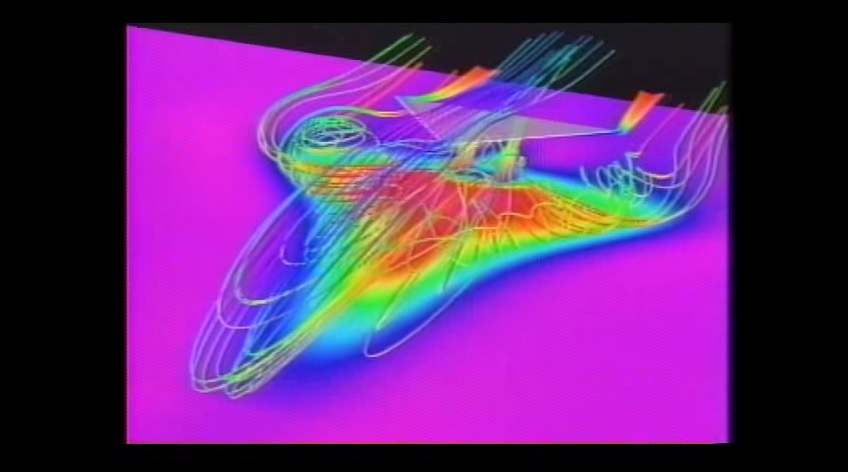

A thermal analysis measures the effects of temperature fluctuations on a design. Heat transfer can be analyzed by means of conduction (in which case we use FEA) or convection and radiation (in which case we use CFD software to investigate the conjugate heat transfer. When using FEA, we may also use the coefficient of thermal expansion to simulate the growth or shrinking of a solid as a result of adding or removing heat.

Thermal analysis is commonly used in various industries, such as aerospace, automotive, electronics, and materials science, to predict and optimize the performance and reliability of products and systems. It can be performed through various methods, including experimental techniques, analytical calculations, convection and radiation (which requires the use of Computational Fluid Dynamics (CFD) software to examine conjugate heat transfer) and/or computer simulations, in which Finite Element Analysis (FEA) is used. When FEA is utilized, the coefficient of thermal expansion can also be incorporated to simulate solid expansion or contraction resulting from the addition or removal of heat.

Why Is Thermal Analysis Important?

Thermal analysis can allow for investigation of design changes and decision validation early on in the development process without the need for building, testing, and destroying an expensive prototype. Since thermal analyses solely focus on temperature, the projects have a quick turnaround time. Here are all the benefits one can reap by performing thermal analysis.

- Early Validation of Design Changes: Thermal analysis allows for early validation of design changes without having to physically build and test prototypes. This helps in identifying and addressing design flaws early on in the development process, which can save time and money in the long run.

- Cost Savings: Thermal analysis can save significant costs by avoiding the need for expensive physical prototypes, testing equipment, and laboratory setups.

- Comprehensive Simulation: Thermal analysis can be linked with other simulation tools such as structural, analysis or fluid, or electromagnetic analysis to provide a more comprehensive simulation of multiple physics simultaneously.

- Optimization of Energy Efficiency: Thermal analysis can help in optimizing the energy efficiency of systems by identifying areas of heat loss and optimizing insulation or cooling systems accordingly.

Thermal Analysis For Design Engineers

Thermal analysis is an important tool for design engineers to optimize product designs, reduce prototyping costs, and ensure efficient operation under different operating conditions. With thermal analysis, design engineers can evaluate the thermal performance of products, identify areas of potential overheating or hot spots, predict thermal behavior under different conditions, and improve product reliability. By using thermal analysis early in the development process, design engineers can identify and address design flaws before physical prototypes are built, saving time and money.

Benefits of Working With Engineering Experts

At Fastway Engineering, we specialize in providing comprehensive thermal analysis services to help design engineers optimize their product designs and ensure efficient operation. Our team of experienced engineers can provide customized thermal analysis solutions tailored to meet the specific needs of each project. Contact us today to learn more about how our thermal analysis services can benefit your design engineering projects.

If you’d like Fastway Engineering to save you time and money with a thermal analysis, please get in touch!